OPTIMIPRO | Projects 2000-2020.

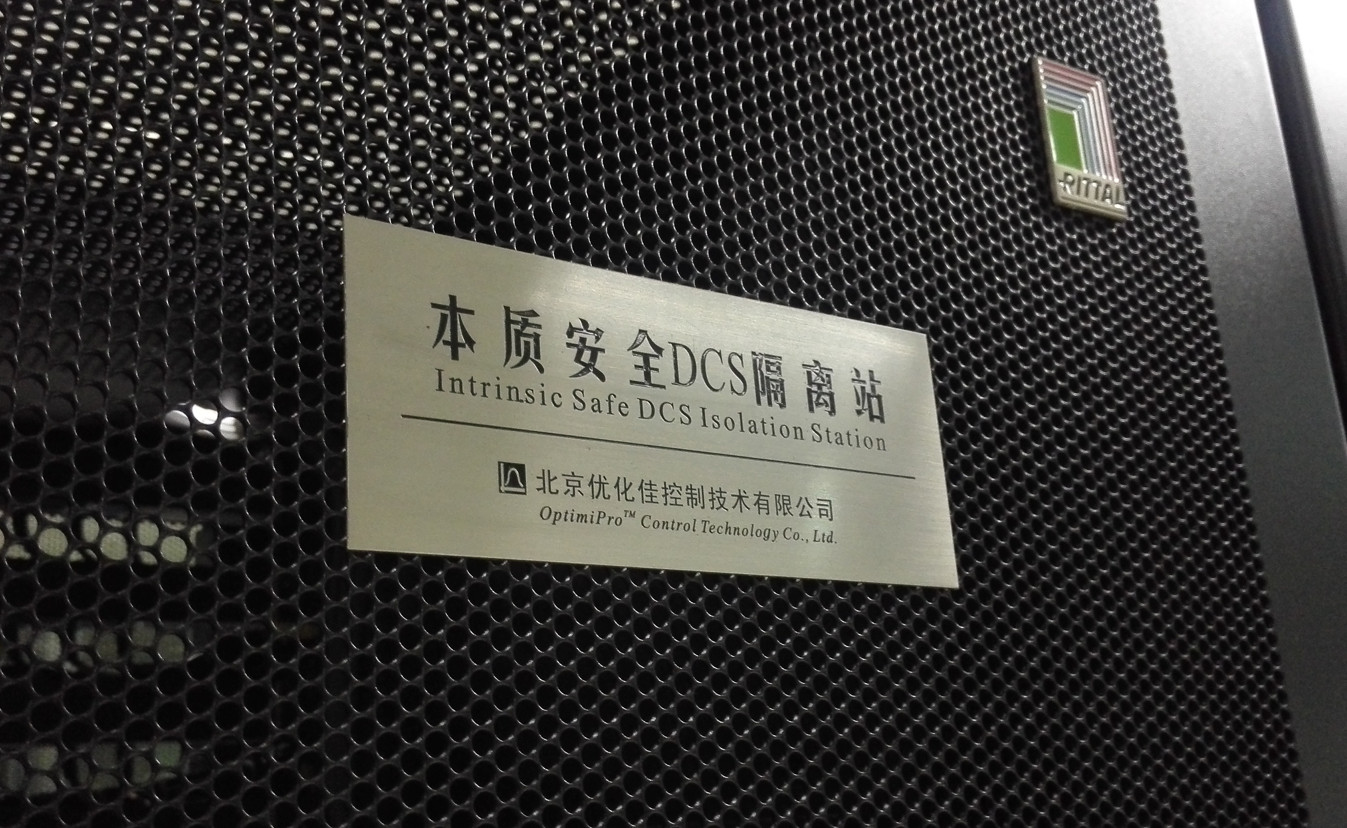

A petrochemical plant in Hunan province has dozens of units, about 50000 tags, and a total of 14 sets of multi input intrinsic safety DCS isolation stations to complete isolation. The isolation project was carried out in two phases, with 9 sets of isolation stations in the first phase and 5 sets of isolation stations in the second phase. Equipped with a DCS isolation station status monitoring system, it can monitor various working conditions and health status of the isolation station in real time. The intrinsic safety DCS isolation system has been operating well and stably since its commissioning in August 2012, and has been fully recognized by various application departments.

The industrial network of a certain refining and chemical plant uses 20 sets of main isolation stations. The 20 sets of equipment in the plant include: 1 # FCCU, 2 # FCCU, 1 # hydrogenation unit, 2 # hydrogenation unit, gas separation unit, polypropylene unit, power, diesel hydrogenation unit, continuous reforming unit, lubricating oil hydrogenation unit, distillation, S-Zorb, etc. An intrinsic safety DCS isolation system is established between DCS and the management network to achieve network security for data transmission of the above devices. At the same time, 3 sets of 1 backup for 8 main station systems are constructed to achieve online redundant backup for all isolation stations of the above 20 devices.

In March 2016, a network security isolation construction project (Phase I) within the institute adopted 7 sets

of intrinsic safety DCS isolation stations to achieve secure file transmission isolation between 23 sets

of DCS systems and ELEN systems of key experimental devices in three research laboratories within the institute was finished.